Anchorage Group explains the difference between variable and constant spring supports

In a variable load support, action forces and reactive forces on the spring varies during the pipe travel and, therefore, it has a zero moment about its line of action. In a constant load support, however, the fixed applied load is constant during its travel while the moment around its pivot point varies.

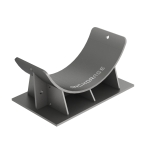

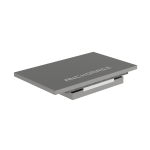

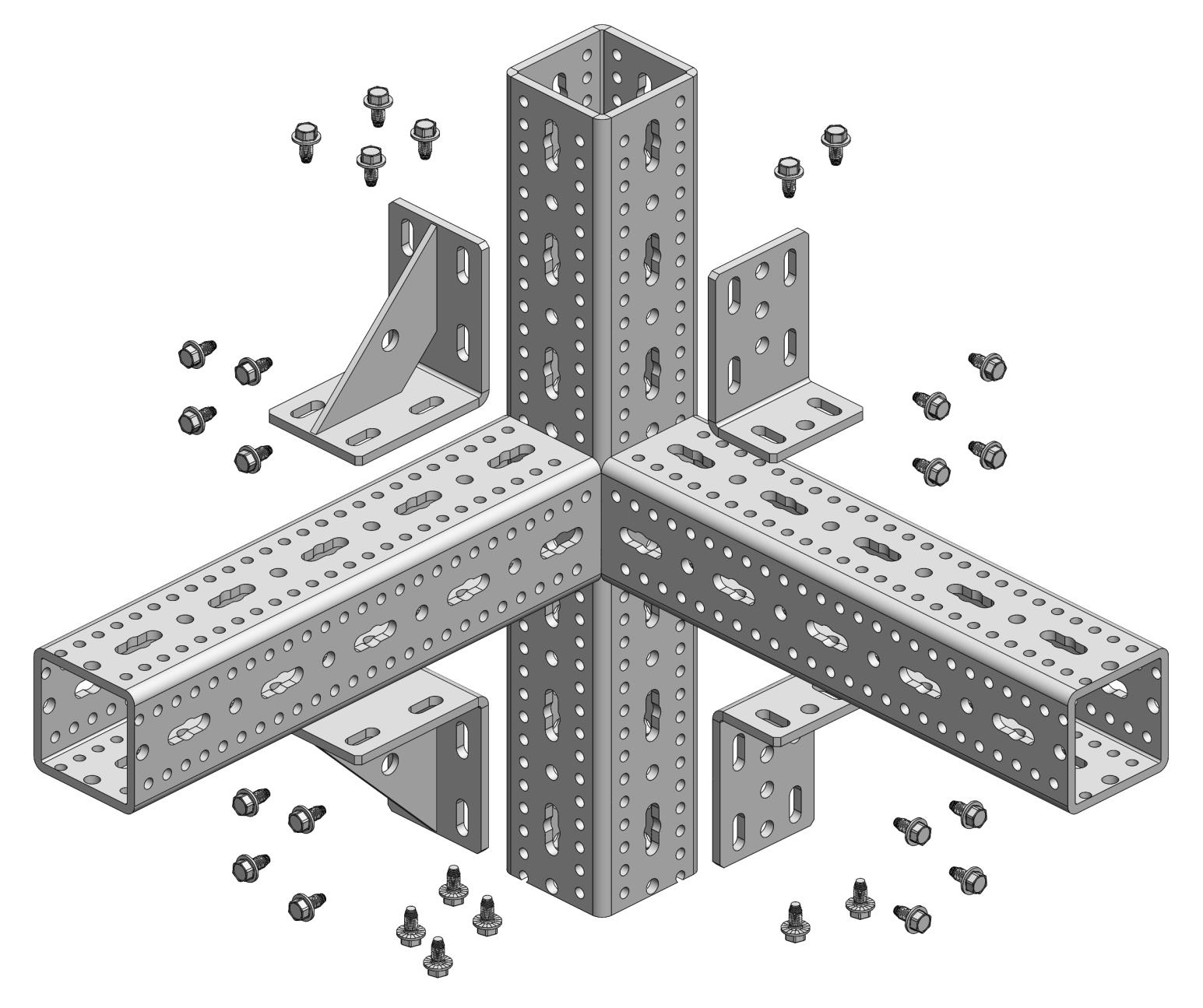

Variable Spring Support

A variable spring is fundamentally a spring in a vessel. When the load “w” is applied onto the system, the spring compresses by a distance W/k (where k is given by the spring rate), while the spring’s reactive force is also “w” under the condition of equilibrium. Deflection (∆L) is developed by pipe movement due to thermal expansion, causing a differential load (∆W=k ● ∆L) to act on the spring. The direction of the move will result in a change of load (∆W), which will either increase or decrease the applied load “w” converting it into our final operating load (w1). To minimize stress variations, the differential load (∆W) for a particular variable spring support is to be limited to a maximum of 25% of the operating load (w1).

Click Here for Variable Spring Products

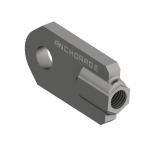

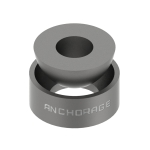

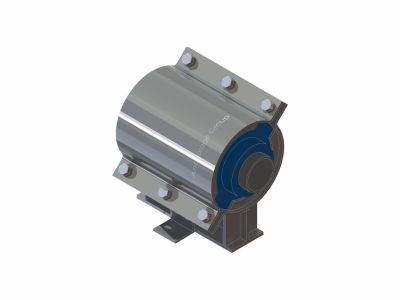

Constant Spring Support

A constant spring is an assembly comprised by a spring and a primary cam mechanism. In this system, the external load remains uniform while the moment around its fixed pivot point varies during displacement (due to changes in moment arm length). An equilibrium is maintained by balancing the external force moment and the internal moment, which is produced by the spring’s compression/decompression around the pivot during pipe travel.

A resisting force, nearly independent of position during its travel, can be provided by selecting proper moment arms, as developed by the cam geometry and spring properties

At each travel location of the external load, the moment resulted by the applied load is in equilibrium with the counter moment caused by the compressed/decompressed spring force with the suitable moment arm.

Typically, the disparity of active and reactive forces is minimal (with a maximum deviation of 6%) it can be taken as a constant force while moving either upward or downward.